According to Fact.MR, the global crusher backing materials market size is slated to expand moderately across the 2020-2030 forecast period. This growth is largely underpinned by surging volumes of mining and mineral extraction activities, which require extensive usage of crushers to break through tough materials.

Crusher backing materials are substances that are used to eliminate gaps or misalignments behind the principal parts of a crusher. Deploying effective crusher breaking compounds and release agents are important for enhancing the life of any crushing equipment, thus helping reduce excessive maintenance costs.

Crusher backing materials offer enhanced impact tolerance, minimum container filler segments, and low shrinkage possibilities. Attributed to these benefits, these materials are highly suitable for various ancillary applications such as bonding, fastening, grouting and filling.

A Detailed Research Report: Read Now

Key Takeaways

- Cone crushers to remain primary crusher backing materials application domain

- Mining and smelting operations to make extensive usage of crusher backing materials

- U.S. to capture an attractive crusher backing materials market share, given the increasing number of hydrocarbon exploration projects

- U.K. to experience positive Y-o-Y growth, with an increase in potash and polyhalite mining operations

- Germany and France to experience steady growth on the back of a rebounding tourism industry, facilitating construction projects in the hospitality segment

- India, China, Japan & South Korea to remain attractive investment hotspots, backed by the rising need for housing and public infrastructure

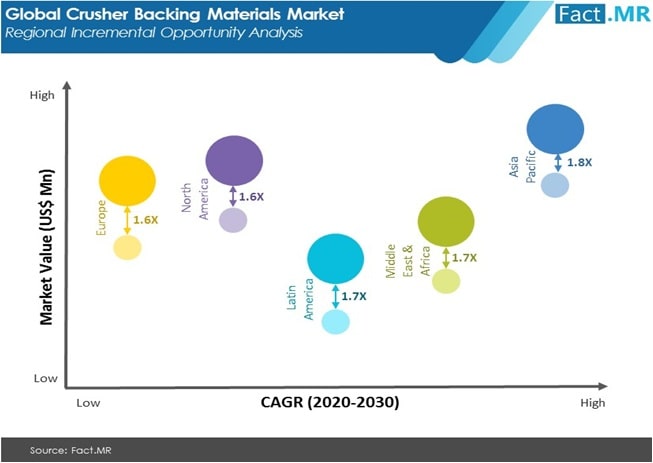

“Increasing frequency of construction and infrastructure projects in the wake of large-scale urbanization is prompting leading crushing backing materials manufacturers to deepen penetration across the emerging markets in Asia-Pacific. This is anticipated to generate fresh revenue ecosystems in forthcoming years,” concludes the Fact.MR analyst.

FREE Sample Copy Is Available: Download Now

Competitive Landscape

Numerous small and medium-scale manufacturers dominate the global crusher backing materials landscape. Prominent players include Henkel Corporation Engineering Adhesives, ITW Performance Polymers, FLSmidth & Co. A/S, ESCO Corporation, HPZ Crusher Services, Columbia Steel Casting Co. Inc., Monarch Industrial Products (I) Pvt. Ltd., Epoxa US, FINNSAD Group Oy, Unnathi Enterprises and Copps Industries.

Leveraging modern production technology is a core expansion strategy adopted by some players. In January 2021, Henkel Corporation announced a partnership with Asiga, a leading 3D printing equipment manufacturer, to assist the former in its Open Materials Platform to accelerate the adoption of additive manufacturing in various industries, including crusher backing materials.

Companies also rely on strategic acquisitions to consolidate their market presence. For instance, in 2018, Weir Group acquired a stake in ESCO Corporation for a sum exceeding US$ 1 billion, at an estimated enterprise value of US$ 1.2 billion to expand its surface mining ground engineering tools (GET) business.

Key Segmentation :

Fact.MR’s research study assesses the global crusher backing materials market in terms of application, end-use industry, and region. This report presents extensive market dynamics and trends associated with different segments of the market and their influence on the growth prospects of the global crusher backing materials market.

Application

- Cone Crushers

- Gyratory Crushers

- Stone Crushers

- Grinding Mills

- Others (including Jaw Crushers and Crusher Buckets)

End-use Industry

- Mining & Smelting

- Building & Construction

Region

- North America

- Latin America

- Europe

- Asia Pacific

- Middle East & Africa